Machine Effectiveness

Increase Productivity by staying on top of Overall Equipment Effectiveness(OEE)

Increase Productivity by staying on top of Overall Equipment Effectiveness(OEE)

OEE is a highly effective manufacturing operation evaluation metric. It quantifies how well a machine performs relative to its designed capacity, during the periods of its scheduled run. It helps maximize output from existing resources to meet customer demands.

Closely monitor your machine's performance from any internet connected device

By using our solution, you can closely monitor the OEE of your machines/shop floor. This will allow you to stay on top of your machine performance to maximize output and increase profits from existing resources.

Turn your machines into Smart Machines by hooking up our solution to your machines

Machine data analytics can help in increased machine & mold life. You can minimize paperwork and manual tracking of rejections by plugging in our IoT solution to your machines and turning them smart.

Cloud Based Data Analytics accessible on all your devices - SmartPhone, Tablet, Laptop, Desktop

We have setup a scalable cloud based platform that allows you to connect any number of machines through our IoT device and quickly get on top of OEE metrics of your machines from anywhere in the world from any of your favorite devices.

Get more out of your molding machines using our complete packaged solution that can be deployed quickly at your facotry floor comprising any number of Injection Molding Machines.

Do you know the overall effectiveness of your machines?

Do you know how efficiently your machines are performing?

Are you considering investing in new machines to meet your growing demand?

Are you collecting and scientifically analyzing machine data?

Is your current analysis of machine data allowing you to make smart decissions about manpower, machine & mold maintenance

Have you considered getting more out of your existing machines?

Before you decide on investing in new machines, consider investing in getting the most out of your existing machines. Our fully automated analytics solution can help optimize your shop floor process and practice. With the ever increasing demand for Plastic Products our solution can help you maximize your profits without investing in new machines.

Chipster offers unique solutions designed for different markets.

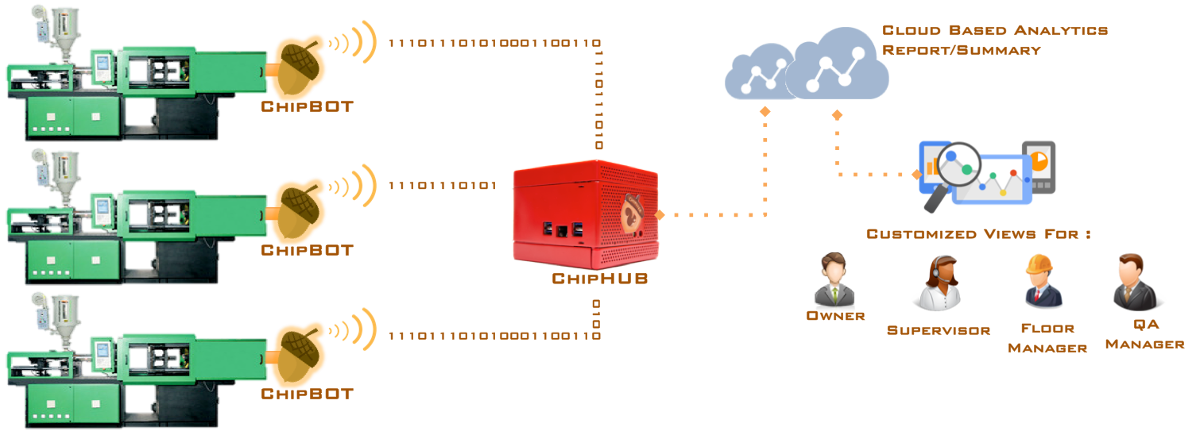

The products that make up the industrial analytics solutions are as follows :

A Wireless IoT module that plugs into any machine that has a Serial, USB or Ethernet port allowing custom analytics solution to be built on top of it for specific needs. Though generic by design, the chipBOT can be customized for different types of machines.

A compact (4 cubic inches) yet powerful modular computing device that receives data from ChipBOT, processes the same and generates required analytics reports. This is a general purpose computing device that can go anywhere a traditional desktop computer is used today.

The Software module that runs on ChipHUB, crunches raw data retrieved from ChipBOT and produces reports customized for individual use. The software also makes this report available over Cloud so that you can access the reports from any internet connected device with a web browser.